Cosmetic Packaging

It is human nature to pursuit for beauty and cosmetic packaging is a catalyze for the beauty industry.

High quality cosmetic packaging product allow to express the essence of niche and fashion brand.

With increasing turnover for more than XX million euro every years, it implied that the competitiveness of this huge market fashion brand need a reliable OEM to achieve

With balance in high clarity, chemical resistant and mechanical strength, Surlyn® is trademark of Dupont Plastic which is widely applied in cosmetic packaging market.

Product thickness with more than 50mm is difficult to control and mass production.

With more than 20 years of experience in handling Surlyn® with multi-cavaties injection, Eagle has served for more than 15 top fashion brands like Chanel, Gucci and Guerlain. Collaborating with our automation team, we try to improve the productivity and efficiency.

Advantages of Surlyn

Surlyn, a versatile thermoplastic material, offers several advantages in various applications:

-

Impact Resistance:

- Surlyn exhibits excellent impact strength, making it suitable for parts that need to withstand mechanical stress or accidental drops.

- Its toughness helps prevent cracking or shattering.

-

Clarity and Transparency:

- Surlyn resins are inherently clear and transparent.

- They maintain their optical properties even after molding, making them ideal for packaging, cosmetic containers, and lenses.

-

Chemical Resistance:

- Surlyn is resistant to a wide range of chemicals, including acids, bases, and solvents.

- This property ensures durability and longevity in harsh environments.

-

Scratch and Abrasion Resistance:

- Surlyn surfaces are less prone to scratches and abrasions.

- It retains its appearance and gloss over time, making it suitable for consumer goods and automotive applications.

-

High Gloss Finish:

- Surlyn can achieve a glossy, polished surface without the need for additional coatings or finishes.

- This feature is advantageous for cosmetic packaging, luxury goods, and decorative items.

-

Easy Processing:

- Surlyn is compatible with standard injection molding equipment.

- It flows well during processing, allowing for intricate part designs.

-

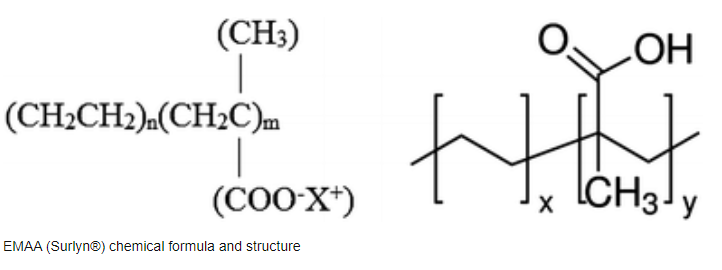

Ionomer Properties:

- Surlyn is an ionomer, which means it has a unique combination of stiffness and flexibility.

- It provides good dimensional stability while remaining flexible enough for certain applications.

-

Low Density:

- Surlyn has a lower density than many other plastics.

- Lightweight parts can be produced without compromising strength.

-

Weather Resistance:

- Surlyn resists UV radiation, moisture, and temperature variations.

- It maintains its properties outdoors, making it suitable for outdoor products.

-

Recyclability:

- Surlyn can be recycled, contributing to sustainable practices.

Remember that the specific advantages depend on the application and grade of Surlyn used. Whether it’s protective packaging, sports equipment, or consumer goods, Surlyn’s versatility makes it a valuable material in the plastics industry!

Surlyn injection molding Difficulties

When injection molding with Surlyn resin, there are specific considerations to keep in mind. Let’s delve into the details:

-

Processing Characteristics:

- Surlyn resin, when injection-molded, exhibits similar characteristics to low-density polyethylene (LDPE) or ethylene copolymer.

- It’s essential to follow the guidelines provided for successful processing.

- Key points are highlighted in bold throughout the guide.

-

Molding Conditions:

- Surlyn is readily processible in conventional molding equipment.

- Barrel Temperature: Adjust the barrel temperatures to achieve the desired melt temperature. The rear zone temperature should be kept low (less than 177°C / 350°F) to prevent bridging.

- Cooling Water: Consider using cooling water on the hopper feed throat instead of hopper drying, which can lead to agglomerates bridging.

- Melt Temperature: Surlyn resins are molded at temperatures ranging from 177 to 243°C (350 to 470°F), depending on the melt index and part geometry.

-

Melt Viscosity and Flow:

- Surlyn’s flow rate increases twice as fast as LDPE with incremental increases in melt temperature.

- As the melt cools (inside the cavity), Surlyn thickens at twice the rate of LDPE.

- Optimal Melt Temperature: Molding at a slightly higher melt temperature than the minimum required allows melt-oriented stresses to relax before ejection, improving part toughness.

-

Surlyn Reflections Resins:

- These thermoplastic alloys, composed of ionomer and polyamide, yield tough, high-gloss parts that require no painting.

- Cleaning the barrel and screw is essential when switching materials.

Remember, while Surlyn offers unique properties, understanding its behavior during injection molding ensures successful outcomes for your plastic parts! 🌟

For more detailed information, you can refer to the official Surlyn molding guide1.